Basic process requirements of Novotrack prefabricated rubber surface system

from bottom to top

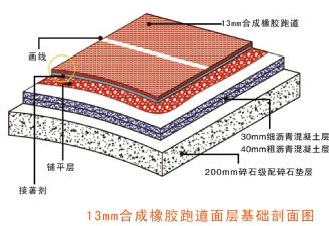

1. Plain soil compaction:Tamped Density 95%.

2. 200mm thick lime soil base with 12% lime content. (According to the groundwater level and regional severe cold conditions, the material composition and thickness of the base layer are determined according to local conditions)

3. 200mm graded crushed stone cushion: coarse gradation thickness of 100mm, crushed stone particle size of 15-25mm, fine gradation thickness of 100mm, particle size of 5-15mm, rolled back and forth with a road roller of more than 8 tons and compacted and leveled. Compact as much as possible, the degree of compaction is determined by the on-site sampling test, (to modify the compaction degree of Platts method 95 - 98%).

4. Adhesive layer: spray asphalt combined with oil as the adhesive layer.

5. 40mm Coarse Asphalt Concrete Layer: Asphalt concrete type is AC-16, in the whole mixture, the content of asphalt should reach 4─6% (by weight). The crushed stone used for blending is solid, angular stone, preferably not shale.

6. 30mm fine asphalt concrete layer: Asphalt concrete type is AC-10, the recommended mineral grading should reach: 5-10mm crushed stone: coarse stone powder: stone chips: mineral powder = 30:25:40:5, the best oil stone ratio is 6.1 %, the optimum asphalt dosage is 5.75%. During the paving process, mechanical paving must be used to ensure that the void ratio of the surface material is not too large. In the whole mixture, the content of asphalt should reach 4-6% (by weight). The crushed stone used for blending is solid, angular stone, preferably not shale.

Construction requirements:

1. Flatness:

The qualified rate of flatness is above 95%, the error of 3-meter ruler is 3mm, or the height of the accumulated water after the water test does not exceed the height of a one-yuan coin

2. Slope:

Horizontal <1%, vertical <1‰, semicircular high jump area <4‰, the surface should be flat and smooth to ensure drainage.

3. Strength and Stability:

Asphalt foundation is best to use bituminous material without wax or with little wax, and the bituminous mixture must be fully compacted. The surface is uniform and solid, smooth without cracks, no rotten edges, no pockmarks, smooth and smooth seams. The compaction density shall not be less than 95%. After being pressed by a medium-sized roller compactor, there shall be no obvious wheel marks, no flaking, no loose soil, no waves, etc.